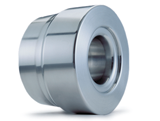

We supply rolls for warm rolled seamless pipes as well as form pipes, rod profiles, welding pipes and driving pipes for pipe welding devices. We optimise the roll material and the centrifugal casting process to the requirements of your specific application.

SIWACO reducing rolls manufactured out of centrifugal compound cast iron are used in areas of high thermal and mechanical demands. Whereby on a normal chilled cast iron roll it is not possible to create a pure hardness depth from over 10% of the roll diameter, using centrifugal compound cast iron it is possible to achieve a defined hardness depth. Hereby, the calibre surface is even, and wear resistant, up to the largest pipe calibres. The surface hardness can be adjusted according to your wishes.

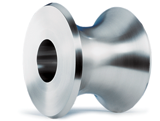

Pipe straightening rolls

The Pipe straightening rolls with a large curvature have a large enough working layer due to the centrifugal compound cast iron.

The straightening rolls are manufactured in one or two parts (coat/axis).

Very accurate machining of the outer shape according to a stencil and then polishing afterwards guarantee the best pipe surfaces.

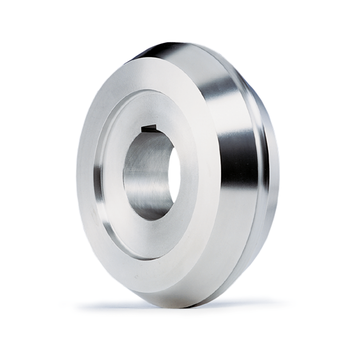

Stretch reducing rolls

Stretch reducing rolls are manufactured mainly according to the centrifugal compound cast iron method. Whereby the various materials can be combined such as: chilled cast iron, nodular iron, indefinite and grey cast iron. For special cases the material qualities chrome steel and special steel are available.

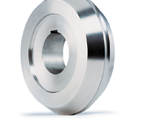

Plug rolls

Plug rolls made of indefinite and nodular iron are wear resistant and at the same time easy to grip. If the wear resistance is more important than the gripping then nodular iron is preferred. The tensile strength can be increased by treating the nodular iron with a special thermal procedure.